Aluminiyamu Kusungunula Crucible Kuponya Clay Graphite

NKHANI ZA PRODUCT

Superior Thermal Conductivity

Kuphatikiza kwapadera kwa silicon carbide ndi graphite kumatsimikizira kutentha kofulumira komanso kofanana, kuchepetsa kwambiri nthawi yosungunuka.

Kukaniza Kutentha Kwambiri

Kuphatikiza kwapadera kwa silicon carbide ndi graphite kumatsimikizira kutentha kofulumira komanso kofanana, kuchepetsa kwambiri nthawi yosungunuka.

Kukaniza Kokhazikika kwa Corrosion

Kuphatikiza kwapadera kwa silicon carbide ndi graphite kumatsimikizira kutentha kofulumira komanso kofanana, kuchepetsa kwambiri nthawi yosungunuka.

MFUNDO ZA NTCHITO

| Graphite /% | 41.49 |

| SiC /% | 45.16 |

| B/C /% | 4.85 |

| Al₂O₃ / % | 8.50 |

| Kuchulukana kwakukulu / g·cm⁻³ | 2.20 |

| Zowoneka bwino / % | 10.8 |

| Kuphwanya mphamvu / MPa (25 ℃) | 28.4 |

| Modulus of rupture/MPa (25 ℃) | 9.5 |

| Moto kukana kutentha / ℃ | > 1680 |

| Kutentha kwamphamvu kukana / Times | 100 |

| Mawonekedwe/Mawonekedwe | A (mm) | B (mm) | C (mm) | D (mm) | E x F kukula (mm) | G x H (mm) |

|---|---|---|---|---|---|---|

| A | 650 | 255 | 200 | 200 | 200x255 | Popempha |

| A | 1050 | 440 | 360 | 170 | 380x440 | Popempha |

| B | 1050 | 440 | 360 | 220 | ⌀380 | Popempha |

| B | 1050 | 440 | 360 | 245 | ⌀440 | Popempha |

| A | 1500 | 520 | 430 | 240 | 400x520 | Popempha |

| B | 1500 | 520 | 430 | 240 | ⌀400 | Popempha |

NJIRA YOTSATIRA

1. Kukonzekera Molondola

High-purity graphite + premium silicon carbide + proprietary binding agent.

.

2.Isostatic Pressing

Kuchulukana mpaka 2.2g/cm³ | Khoma makulidwe kulolerana ± 0.3m

.

3.Kutentha Kwambiri Sintering

SiC tinthu recrystallization kupanga 3D maukonde dongosolo

.

4. Kukulitsa Pamwamba

Anti-oxidation zokutira → 3 × kukana dzimbiri bwino

.

5.Kuyang'ana Kwabwino Kwambiri

Nambala yapadera yolondolera kuti muzitha kutsatira moyo wonse

.

6.Chitetezo Packaging

Wosanjikiza wosanjikiza + Wotchinga chinyezi + Chotsekereza cholimbitsa

.

PRODUCT APPLICATION

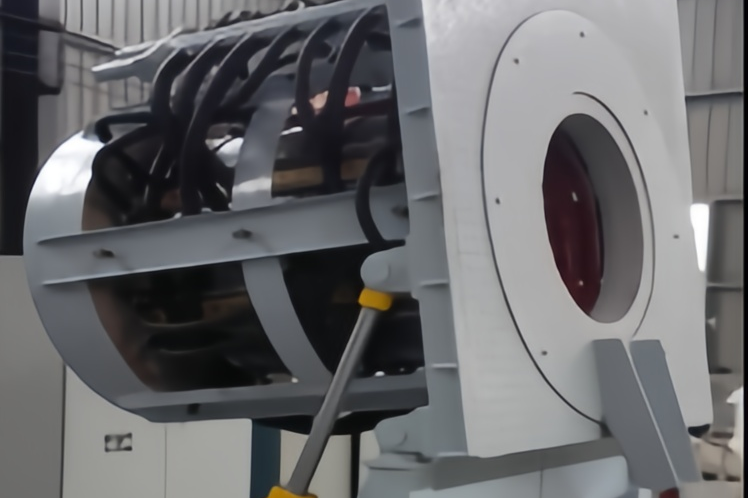

Ng'anjo Yosungunula Gasi

Ng'anjo Yosungunula Induction

Resistance Melting ng'anjo

N’CHIFUKWA CHIYANI MUTISANKHE?

FAQS

Q1: Kodi ubwino wa silicon carbide graphite crucibles poyerekeza ndi miyambo graphite crucibles?

✅Kulimbana ndi Kutentha Kwambiri: Ikhoza kupirira 1800 ° C nthawi yaitali ndi 2200 ° C yochepa (vs. ≤1600 ° C kwa graphite).

✅Moyo Wautali: 5x kukana kwamphamvu kwamafuta, 3-5x kutalika kwa moyo wautumiki.

✅Zero Kuipitsidwa: Palibe mpweya wolowera, kuonetsetsa chiyero chosungunuka chachitsulo.

Q2: Ndi zitsulo ziti zomwe zingasungunuke muzitsulo izi?

▸Common Metals: Aluminiyamu, mkuwa, nthaka, golide, siliva, etc.

▸Zitsulo Zogwira Ntchito: Lithiamu, sodium, calcium (imafuna ₃N₄ ₃ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ ₄ kuyanika

▸Refractory Metals: Tungsten, molybdenum, titaniyamu (imafuna vacuum / inert gasi).

Q3: Kodi ma crucibles atsopano amafunikira kuthandizidwa asanagwiritse ntchito?

Kuphika Kovomerezeka: Pang'onopang'ono kutentha kwa 300 ° C → gwirani kwa maola awiri (kuchotsa chinyezi chotsalira).

Choyamba Sungunulani Malangizo: Sungunulani zinyalala zotsalira poyamba (zimapanga zosanjikiza zoteteza).

Q4: Kodi mungapewe bwanji kusweka kwa crucible?

Osalipira zinthu zozizira mu crucible yotentha (max ΔT <400°C).

Kuzizira pambuyo pa kusungunuka <200°C/ola.

Gwiritsani ntchito ziboliboli zodzipatulira (peŵani kukhudzidwa ndi makina).

Q5: Kodi mungapewe bwanji kusweka kwa crucible?

Osalipira zinthu zozizira mu crucible yotentha (max ΔT <400°C).

Kuzizira pambuyo pa kusungunuka <200°C/ola.

Gwiritsani ntchito ziboliboli zodzipatulira (peŵani kukhudzidwa ndi makina).

Q6: Kodi chiwerengero chocheperako (MOQ) ndi chiyani?

Zitsanzo Zokhazikika: 1 chidutswa (zitsanzo zilipo).

Mapangidwe Amakonda: 10 zidutswa (CAD zojambula zofunika).

Q7: Kodi nthawi yotsogolera ndi chiyani?

⏳Zinthu za In-Stock: Zimatumizidwa mkati mwa maola 48.

⏳Maoda Mwamakonda: 15-25masikukupanga ndi masiku 20 nkhungu.

Q8: Kodi mungadziwe bwanji ngati crucible yalephera?

Ming'alu> 5mm pakhoma lamkati.

Kuzama kwachitsulo> 2mm.

Kusintha> 3% (yezerani kusintha kwa m'mimba mwake).

Q9: Kodi mumapereka chitsogozo chosungunula?

Kutentha kokhotakhota kwa zitsulo zosiyanasiyana.

Makina owerengera mtengo wa gasi wolowera.

Slag kuchotsa kanema maphunziro.