Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

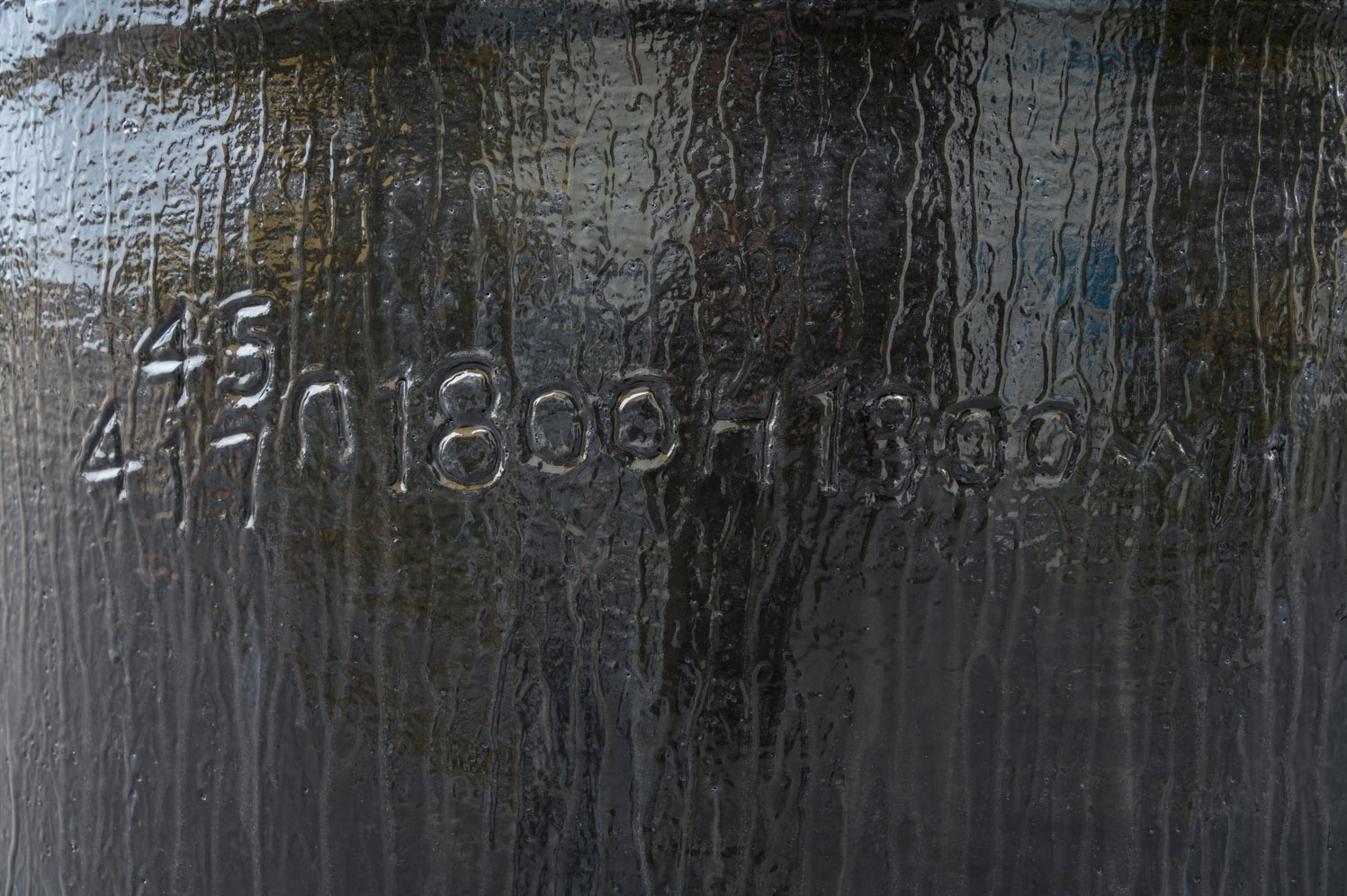

Kusungunula crucible kwa zitsulo zopanda chitsulo Kusungunula ndi Kuponya

NKHANI ZA PRODUCT

Kusungunuka Kwachangu

High matenthedwe madutsidwe graphite zinthu bwino matenthedwe dzuwa ndi 30%, kwambiri kuchepetsa nthawi kusungunuka.

Superior Thermal Shock Resistance

Ukadaulo wolumikizidwa ndi resin umalimbana ndi kutentha komanso kuziziritsa mwachangu, kulola kulipira mwachindunji popanda kusweka.

Kukhalitsa Kwapadera

Mphamvu zamakina zapamwamba zimatsutsa kukhudzidwa kwa thupi ndi kukokoloka kwa mankhwala kwa moyo wautali wautumiki.

MFUNDO ZA NTCHITO

| Graphite /% | 41.49 |

| SiC /% | 45.16 |

| B/C /% | 4.85 |

| Al₂O₃ / % | 8.50 |

| Kuchulukana kwakukulu / g·cm⁻³ | 2.20 |

| Zowoneka bwino / % | 10.8 |

| Kuphwanya mphamvu / MPa (25 ℃) | 28.4 |

| Modulus of rupture/MPa (25 ℃) | 9.5 |

| Moto kukana kutentha / ℃ | > 1680 |

| Kutentha kwamphamvu kukana / Times | 100 |

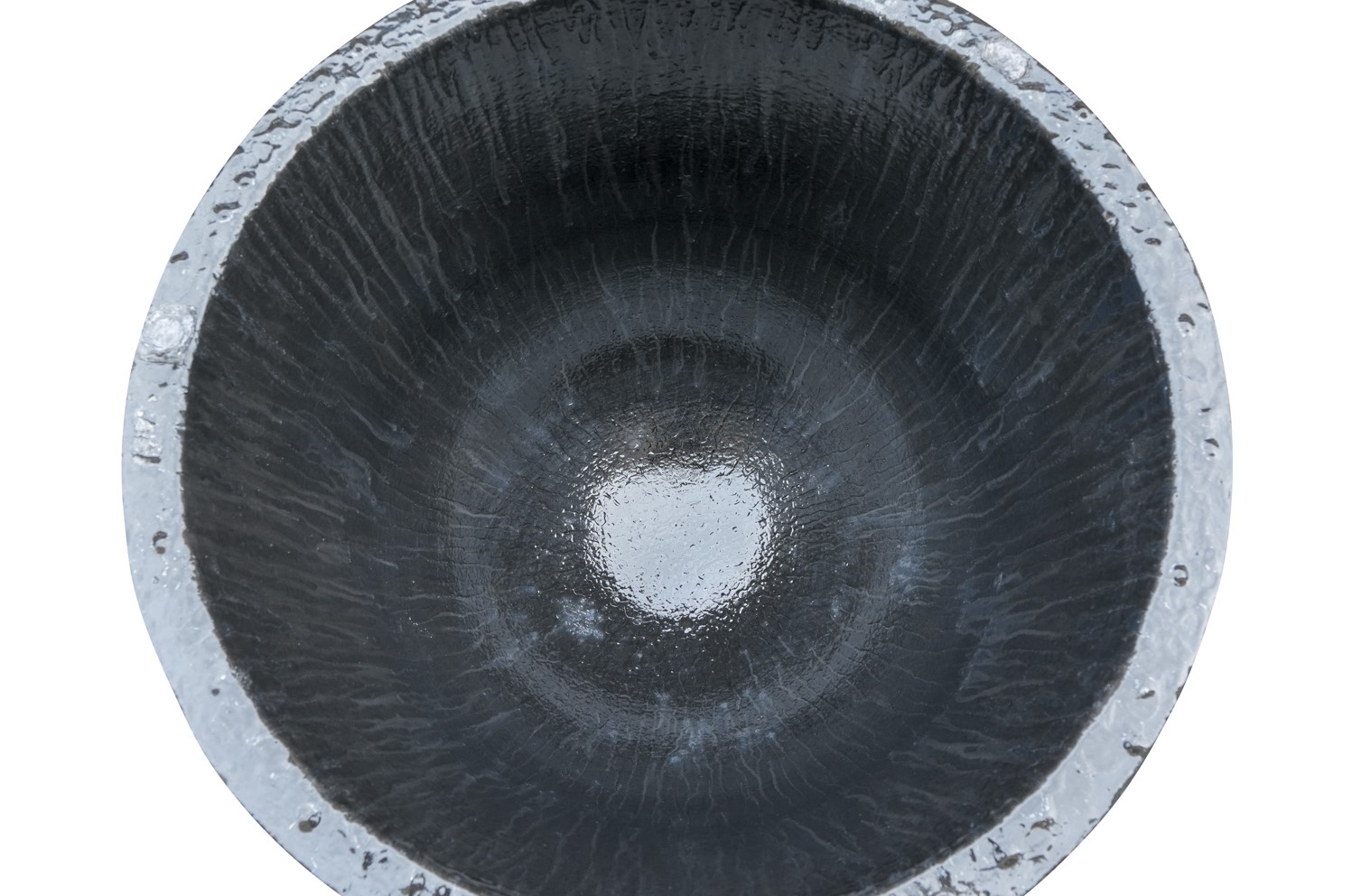

| No | Chitsanzo | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180 # | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| Mtengo wa RA350 | 349 # | 590 | 460 | 230 |

| Mtengo wa RA350H510 | 345 # | 510 | 460 | 230 |

| Mtengo wa RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| Mtengo wa RA600 | 501 # | 700 | 530 | 310 |

| RA800 | 650 # | 800 | 570 | 330 |

| RR351 | 351 # | 650 | 420 | 230 |

NJIRA YOTSATIRA

1. Kukonzekera Molondola

High-purity graphite + premium silicon carbide + proprietary binding agent.

.

2.Isostatic Pressing

Kuchulukana mpaka 2.2g/cm³ | Khoma makulidwe kulolerana ± 0.3m

.

3.Kutentha Kwambiri Sintering

SiC tinthu recrystallization kupanga 3D maukonde dongosolo

.

5.Kuyang'ana Kwabwino Kwambiri

Nambala yapadera yolondolera kuti muzitha kutsatira moyo wonse

.

4. Kukulitsa Pamwamba

Anti-oxidation zokutira → 3 × kukana dzimbiri bwino

.

6.Chitetezo Packaging

Wosanjikiza wosanjikiza + Wotchinga chinyezi + Chotsekereza cholimbitsa

.

PRODUCT APPLICATION

Zoyenera zitsulo zambiri zopanda chitsulo

Sungunulani Aluminium

Sungunulani Copper

Sungunulani Golide

N’CHIFUKWA CHIYANI MUTISANKHE?

FAQS

Q1: Kodi Crucible Cover ingachepetse ndalama zamagetsi?

A: Ndithu! Amachepetsa kutaya kutentha, kuchepetsa kugwiritsa ntchito mphamvu mpaka 30%.

Q2: Ndi ng'anjo ziti zomwe zimagwirizana?

Yankho: Imagwira ntchito zosiyanasiyana—yoyenera kulowetsamo, gasi, ndi ng’anjo yamagetsi.

Q3: Kodi graphite silicon carbide ndiyotetezeka kutentha kwambiri?

A: Inde. Kukhazikika kwake kwamafuta ndi mankhwala kumapangitsa kuti ikhale yabwino pamikhalidwe yovuta kwambiri.

Q4: Kodi mungapewe bwanji kusweka kwa crucible?

Osalipira zinthu zozizira mu crucible yotentha (max ΔT <400°C).

Kuzizira pambuyo pa kusungunuka <200°C/ola.

Gwiritsani ntchito ziboliboli zodzipatulira (peŵani kukhudzidwa ndi makina).

Q5: Kodi mungapewe bwanji kusweka kwa crucible?

Osalipira zinthu zozizira mu crucible yotentha (max ΔT <400°C).

Kuzizira pambuyo pa kusungunuka <200°C/ola.

Gwiritsani ntchito ziboliboli zodzipatulira (peŵani kukhudzidwa ndi makina).

Q6: Kodi chiwerengero chocheperako (MOQ) ndi chiyani?

Zitsanzo Zokhazikika: 1 chidutswa (zitsanzo zilipo).

Mapangidwe Amakonda: 10 zidutswa (CAD zojambula zofunika).

Q7: Kodi nthawi yotsogolera ndi chiyani?

⏳Zinthu za In-Stock: Zimatumizidwa mkati mwa maola 48.

⏳Maoda Mwamakonda: 15-25masikukupanga ndi masiku 20 nkhungu.

Q8: Kodi mungadziwe bwanji ngati crucible yalephera?

Ming'alu> 5mm pakhoma lamkati.

Kuzama kwachitsulo> 2mm.

Kusintha> 3% (yezerani kusintha kwa m'mimba mwake).

Q9: Kodi mumapereka chitsogozo chosungunula?

Kutentha kokhotakhota kwa zitsulo zosiyanasiyana.

Makina owerengera mtengo wa gasi wolowera.

Slag kuchotsa kanema maphunziro.

Nkhani Yophunzira #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Nkhani Yophunzira #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Umboni

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, et feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe